You may want to have a deep research in how does a commercial ice maker work, even when you fully understand how does ice maker work. Why? A commercial ice maker is industrial grade, and generally has sophisticated engineering designed to handle continuous operation and higher production demands. People who are looking to this question are mostly business owners, who fully grasp how a commercial ice maker work will have upper hand in choosing the best commercial ice maker to win the competition.

In general, the commercial ice maker doesn’t stray far from the traditional ice making engineering, but it has a few things different from the common, residential countertop ice makers. I also prepare an article on how to install undercounter ice maker, to bring you full knowledge on these commercial, industrial ice makers.

I’ve made a comprehensive “Ice Maker FAQ” series collecting all common ice maker problems to help Ice Artisan readers quickly troubleshoot their ice maker units.

- ⚖️ Countertop vs undercounter ice makers

- 👍 Are portable ice makers worth it?

- ⚡ How much electricity does an ice maker use?

- 💧 Does an ice maker use a lot of water?

- 🪣 Do ice makers need to be drained?

- 🚫 Can ice makers cause water damage?

- 🚰 Do ice makers need water lines?

- 🔊 Are countertop ice makers loud?

- 😭 Do ice makers make a lot of noise?

- 🔗 Are countertop ice makers safe?

- ⛺ Can ice makers be used outdoors?

- 🔌 Can ice makers be left running all the time?

- 🚗 Can ice makers be used in RV?

- 🗄️ Can ice makers be installed in cabinets?

- ❄️ Do portable ice makers keep ice frozen?

- 🛠️ Can ice makers be used in garages?

- 📄 Do ice makers store ice?

- 🚀 How do ice makers make ice so fast?

- 💡 How does ice maker work?

- 🎰 How does a commercial ice maker work?

- 🛠️ How to install an undercounter ice maker?

- ❄️ How to make clear ice in ice maker?

- 🪣 How to increase ice production in ice maker?

- ⏳ How long does an ice maker take to make ice?

- 🔗 When to replace ice maker filter?

- ⏱️ When to replace ice maker?

- 💡 How to clean ice maker?

- 😭 Why does my ice maker smell bad?

- 🫗 How to drain an ice maker?

- 🪣 How to unclog an ice maker?

- 🔗 How do I unstick my ice maker arm?

- 💧 How to fix ice maker leaking water?

- ❄️ Why is my portable ice maker making too much ice?

- 🥵 Why is my ice maker hot?

- 🔌 What happens if you don’t turn off the ice maker?

- 🧊 How to fix ice maker not making ice?

Ice Artisan‘s best picks

How does a commercial ice maker work?

A commercial ice maker employs high-performance compressors (typically 1/5 to 1/2 horsepower) that pressurize refrigerant to 175-275 PSI, creating the temperature gradient necessary for efficient ice production. The refrigerant – commonly R134a or R404A – circulates through sealed copper tubing with diameters ranging from 1/4″ to 3/8″. This circulation creates a continuous heat exchange process where evaporator temperatures remain between 10°F and -5°F (-12°C to -20°C), ready for ice making.

The cycle begins when the compressor runs. As refrigerant absorbs heat from the water, it transitions from liquid to gas in the evaporator. The heated refrigerant then travels to the condenser, where ambient air or water cooling removes the absorbed heat, returning the refrigerant to its liquid state. This process creates a temperature differential of approximately 40°F between the evaporator and the water, enabling rapid freezing within 10-30 minutes per cycle.

How does a commercial ice maker work? Step-by-step

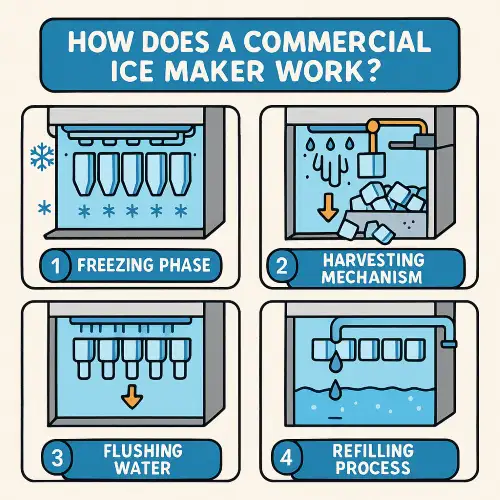

To help you visually capture how a commercial ice maker works, I made this infographic that breaks down the entire process in a clear, visual way.

Step 1: Freezing phase

During the freezing phase, water flows over the evaporator plate or specially designed molds at a controlled rate of 0.5-2 gallons per minute. The water makes contact with surfaces maintained at approximately 22°F (-5.5°C), initiating ice making. Commercial ice makers have precision water distribution systems that ensure uniform freezing patterns, resulting in consistent ice formation across all portions of the evaporator plate or molds.

Step 2: Harvesting mechanism

Once ice forms at desired thickness (typically 1/8″ to 1″ depending on the ice size), the harvest cycle begins. The system briefly reverses, sending hot refrigerant gas (95°F to 120°F) through the evaporator. This creates a 1-2mm layer of meltwater between the ice and evaporator surface. By gravity or mechanical assistance, it releases the ice, which falls into an insulated storage bin capable of maintaining temperatures below 35°F for extended periods.

Step 3: Flushing system

Commercial ice makers incorporate sophisticated flushing systems that remove mineral-laden water after each cycle. This critical step prevents scale buildup that can reduce efficiency by up to 25% if left untreated. The flushing cycle typically purges 15-20% of the water used in each cycle, ensuring fresh water for the next production round.

Stage 4: Refilling process

Finally, the precision floats or electronic water level sensors trigger a refill phase. These systems maintain water levels with ±1/8″ accuracy, ensuring optimal freezing conditions for the subsequent cycle. The entire process repeats automatically until the storage bin reaches capacity, detected by infrared or mechanical sensors.

Key components in a commercial ice maker

Commercial ice makers rely on several specialized components that determine their efficiency and production capacity:

Water inlet valve: Operates at water pressures between 20-80 PSI, controlling flow rates of 0.5-5 gallons per minute depending on machine capacity. A commercial ice maker needs water lines.

Evaporator plate/molds: Constructed from food-grade stainless steel or copper with nickel plating, these surfaces maintain thermal conductivity ratings of 230-380 W/m*K, significantly higher than residential models.

Condenser unit: Either air-cooled (requiring 150-250 cubic feet of air circulation per minute) or water-cooled (using 0.5-1.5 gallons of water per pound of ice produced), these components dissipate heat at rates of 5,000-12,000 BTU/hr.

Control board: Modern units feature microprocessor-controlled systems that make 10-20 operational adjustments per minute, maintaining optimal temperature differentials of ±2°F regardless of ambient conditions between 50°F and 100°F.

Different commercial ice types

Commercial ice makers produce various ice types through specialized mechanisms:

Cube ice: Generate clear, solid cubes by employing vertical evaporator plates with cells or horizontal grid systems. These machines produce ice with density ratings of 0.85-0.92 g/cm³, creating slower-melting ice ideal for beverage service.

Flake ice: Utilize rotating augers against cylindrical evaporators, scraping ice at thicknesses of approximately 2-3mm. These systems operate at faster cycle times (3-6 minutes) while consuming 15-20% less energy than cube producers per pound of ice.

Nugget ice: Combines aspects of cube and flake systems by compressing flaked ice through extrusion dies at pressures of 30-50 PSI, creating the characteristic soft, chewable texture with 60-70% of the density of cube ice.

Now you fully grasp on how does a commercial ice maker work, I hope you find the commercial ice maker a great investment when you really need ice to combat the heat of summers.